DIY Apple Crusher: 3 Working Crusher Options

A crusher is used to grind apples and other fruits to make juicing easier and produce more natural juice. Read this article to learn about the different types of homemade tools, their components, and how to assemble them.

Content

DIY Apple Crusher

The feasibility of making a homemade crusher is supported by a number of advantages of the device. Recycling The harvest will take less time, and there will be virtually no waste. All the juice will be extracted, and the remaining pulp can be used for jam and other food products. A home crusher requires little investment, saves labor, and is ideal for a garden plot. If the device breaks down, repairing it yourself is easy, as all the parts are known and readily available.

The feasibility of making a homemade crusher is supported by a number of advantages of the device. Recycling The harvest will take less time, and there will be virtually no waste. All the juice will be extracted, and the remaining pulp can be used for jam and other food products. A home crusher requires little investment, saves labor, and is ideal for a garden plot. If the device breaks down, repairing it yourself is easy, as all the parts are known and readily available.

What does it consist of?

A homemade design differs from a store-bought crusher not only in appearance but also in its components. Performance can be improved by customizing the design to meet specific needs.

A homemade design differs from a store-bought crusher not only in appearance but also in its components. Performance can be improved by customizing the design to meet specific needs.

An electric grinder will speed up and simplify the process. To save money, you don't need to buy a motor—a motor from an old washing machine will do. A sample list of components: cutting disc (blade), electric motor support, body, cover, control unit.

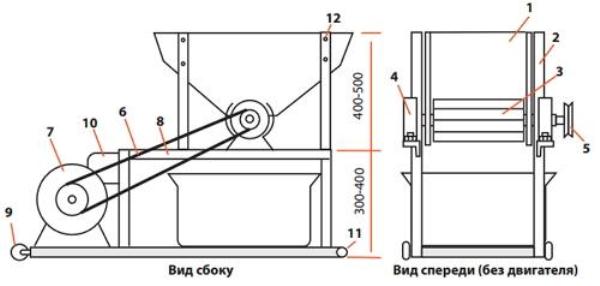

1 – housing, 2 – stiffening angle, 3 – working shaft, 4 – bearing boxes, 5 – belt drive pulley,

6 – belt, 7 – electric motor, 8 – frame, 9 – rollers, 10 – control unit,

11 – transport handle, 12 – housing mounting bolts with stiffening corners

What you will need for production

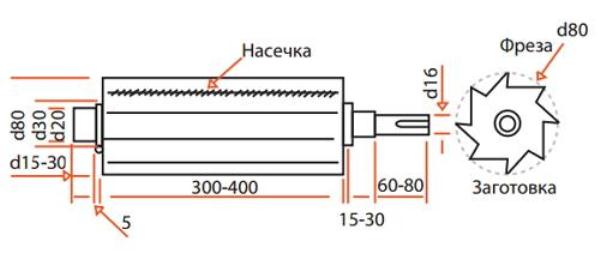

One grinder design begins with the lathe-making of stainless steel shaft steps and bearings (diameter 80 mm). An octagonal toothed shaft is machined on a milling machine. Triangular notches are cut along the teeth using an angle grinder to improve grinding.

One grinder design begins with the lathe-making of stainless steel shaft steps and bearings (diameter 80 mm). An octagonal toothed shaft is machined on a milling machine. Triangular notches are cut along the teeth using an angle grinder to improve grinding.

A top-loading washing machine can serve as the crusher body. When cut into 4 pieces, two side and two end pieces are produced. The blanks are placed in a box, and the seams are welded. Before welding the side pieces, the lower part of the metal is slightly bent to create a gap between the body wall and the drive shaft.

Standard circular saw bearings secure the shaft. A metal angle is used to make the support frame. A plank base is suitable for the base. The control unit features an on/off button. Belt tensioning is simple: first, secure with a bolt, then slide the housing along the guides. Rollers and a handle are bolted to the metal frame for easy transport and operation of the shredder.

A homemade housing made from a washing machine is bolted to the top of the frame. The motor is mounted on the side to prevent juice splashes.

DIY Apple Chopper

Crusher manufacturing begins with understanding the operating principle and the purpose of each component. This knowledge forms the basis for the drawings. All that remains is to choose the most interesting option from those listed below.

From a drill

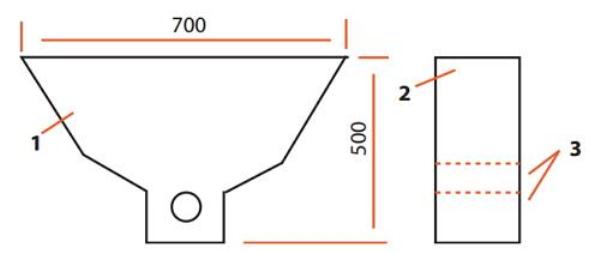

You'll need a compact 350-watt drill. The hopper is made of laminated chipboard, and a drum is used to grind the fruit. The hopper isn't attached; it simply sits on top of the structure.

You'll need a compact 350-watt drill. The hopper is made of laminated chipboard, and a drum is used to grind the fruit. The hopper isn't attached; it simply sits on top of the structure.

The worktop is a small section of laminated tabletop with a hole and 60 x 40 mm pine beams positioned on either side. Oak planks are screwed to the beams. Holes are drilled in the planks for a dowel to secure the drum.

To make the drum, you'll need four pieces of beech wood trim (25 mm thick). The pieces are bonded with acrylic adhesive. The finished 100 x 100 mm timber is planeed to a round shape, and a hole is made along the center for mounting the dowel. 70 mm long screws are screwed into the drum, ensuring the heads protrude approximately 10 mm above the surface.

The final stages include installing the juice and pulp containers, and assembling the components. This design allows you to crush a bucket of apples in 20 minutes, yielding up to 5 liters of juice.

Made of metal

Materials suitable for making a crusher can be found in your garden. Drawings of various designs are available on specialized forums. These are used to plan the dimensions of the components, mounting methods, and specific features of the machine.

Materials suitable for making a crusher can be found in your garden. Drawings of various designs are available on specialized forums. These are used to plan the dimensions of the components, mounting methods, and specific features of the machine.

All parts that come into contact with food are made of stainless steel.

The metal apple crusher is assembled from the following parts:

- sheet metal;

- drum (from a vertical washing machine will do);

- steel shaft;

- rollers with bearings;

- boards;

- start button;

- metal corner;

- motor;

- connecting wires;

- fasteners;

- power plugs.

To complete the job, you will need a welding machine, a commercial and milling machine, an angle grinder, metal shears, bolt wrenches, and a power tool for connecting the wiring and a start button.

Work progress:

- Use a drawing from a forum as a basis or develop your own. Determine the dimensions of the structure and assembly details.

- Using a lathe, make steps on a sheet of metal for mounting bearings and a steel shaft.

- Using a milling machine, remove 8 faces from a steel shaft and make notches.

- Weld a frame from the corner.

- Make a base for the cake container from boards.

- Assemble the remote control from wires and buttons.

- Attach rollers to the bottom of the frame.

- Install the motor in the casing on the side.

Made of wood

A wooden structure is easier to assemble than its metal counterpart. First, you'll need wood that doesn't absorb moisture.

A wooden structure is easier to assemble than its metal counterpart. First, you'll need wood that doesn't absorb moisture.

The wooden apple crusher is assembled from the following parts:

- shaft (wooden, metal);

- thick plywood or boards;

- bearings;

- wide-head screws;

- working drill.

To work you will need metalworking tools, a saw or jigsaw, and a drill.

Work progress:

- Build a bin for loading apples from lumber. You'll need three horizontal walls and one inclined one.

- Make a shaft and attach screws to it. The screw heads will act as cutting elements. It's recommended to arrange the screws in a spiral, which will improve the machine's performance.

- Build a working chamber of optimal dimensions from wood. Make a hole on one side for cleaning out the pulp.

- Insert a pin into the drill cam instead of a drill bit and secure it to the shaft – this will create an analogue of an electric motor.

By choosing the most suitable option from the listed options, you can make natural juice from your own harvest and store-bought fruit. The crusher is easy to make and requires minimal investment. Besides apples, the crusher can handle pears and other fruits.