DIY High-Performance Apple Juicer

Owners of garden plots and summer cottages often face the challenge of preparing a bountiful harvest for storage. It's impossible to quickly prepare it using ordinary household appliances. recycle A large number of berries and fruits are available, while powerful units can be quite expensive. A high-performance juicer, made at home, is the solution.

Content

How to make an apple juicer yourself

Assembling a juicer yourself isn't particularly difficult due to its relatively simple design. However, to properly assemble this device, it's necessary to understand its components and functional features.

How juice extractors work

Juice is extracted by applying pressure to the loaded raw material—fruit or berries. This process can be simultaneous or sequential; for example, with auger-type machines, the finished product is extracted directly during the raw material's crushing. However, assembling such machines is complex and expensive. In contrast, centrifugal machines first crush the fruit in a centrifuge and only then pass it through a press.

Depending on the operating principle, juicers are divided into several types:

Depending on the operating principle, juicers are divided into several types:

- pneumatic;

- mechanical;

- hydraulic;

- electrohydraulic.

The most common type of device assembled at home is a mechanical one, due to its simple assembly. In this design, a piston driven by a simple screw mechanism exerts pressure on the raw material during operation.

The fruits are placed in a perforated container, where intense pressure causes them to release juice. The resulting juice flows through holes punched in the container's walls into a tray.

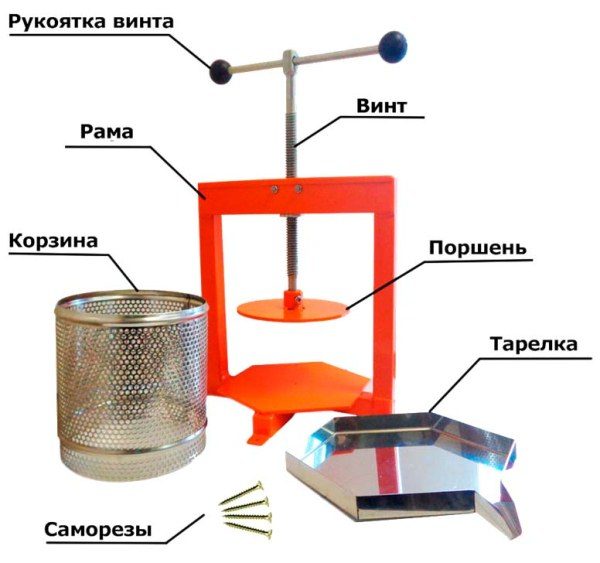

Structural elements

Regardless of the type of juicer (centrifugal or auger) you plan to assemble, you will need the following components:

- bunker for storing raw materials;

- mechanism for grinding and squeezing;

- juice filter;

- pomace collection tank.

Further complexity of the design is determined by the technical capabilities of the unit.

The best option is manual grinding followed by processing in a screw press. More sophisticated models include a mechanically driven grinder.

Making a screw-type juicer that simultaneously crushes and squeezes will require more financial and time investment.

DIY Apple Juicer from a Jack

The jack-based design allows you to squeeze juice without applying physical effort.

What you will need

To make the device you will need several elements:

- Support – keeps the juicer on the ground and ensures its balance. It can be constructed from either wood or metal components.

- The main body can have any shape depending on the materials used. The volume of this element determines the number of fruits that can be processed at once.

- The raw material fixing grid prevents slipping that occurs due to the large amount of juice squeezed out.

- A pressure device—it's the pressure that causes the fruit to release juice. It's best if this mechanism is piston-type.

- A means of facilitating the lifting of a piston or jack.

- Elements that make work easier: pressure jack and screw handle.

- A vessel to hold the finished juice. It's best to use a container with a larger capacity than the amount of juice you'll be juicing at one time, as this will prevent spills.

Step-by-step instructions

Manufacturing sequence:

- Choosing a jack. For assembly, you can use either a hydraulic or manual jack. The advantage of the former is ease of use and convenience, but the disadvantage is that it is completely stationary. A manual jack, on the other hand, can be returned to its original position after juicing.

- Building the frame. The structure must be steel and capable of supporting the weight of the tray, barrel, and fruit. Welded construction is ideal, as the juicer's power depends on its strength.

- The barrel for pressing is constructed. It can be wooden or metal, but must have holes in the bottom and sides for juice drainage. The finished barrel is secured to the frame: a metal barrel is welded, while a wooden barrel is mounted on crossbars and secured with metal fasteners, preventing any slipping or shifting.

- Making a jack stand. This is usually done by joining several wooden planks together.

- Creating gaskets from drainage and a container/tray into which the finished juice will flow.

- Connecting the jack. The element is placed on a support and moved manually.

Before use, a homemade juicer must be thoroughly washed and dried.

DIY Apple Juicer from a Washing Machine

An old washing machine is ideal for creating a centrifugal unit for processing berries, fruits and vegetables.

Among the many features of this appliance is a spin wringer, allowing you to quickly spin large quantities of laundry. Both top-loading and front-loading machines are suitable, but they must have a belt drive, as direct-drive models are not suitable. Front-loading appliances must be placed with the door facing upward.

What you will need

Before you begin assembly, you need to prepare the following:

- fasteners: 3 mm bolts and nuts;

- 2 metal meshes (30 × 6);

- juice collecting container;

- rubber plugs;

- drain pipe;

- Bulgarian;

- wrenches;

- welding machine;

- set of screwdrivers;

- pliers;

- drill;

- metal shears;

- hammer.

In addition, you will need blocks to support and secure the washing machine.

Step-by-step manufacturing instructions

To assemble a juicer from a washing machine, you should begin by preparing the body, following the following algorithm:

- Remove the drive belt from the pulley and pull it towards you.

- Bend back the sealing rubber, remove the cuff and clamp.

- After unscrewing the bolts, remove the shock absorbers.

- Remove all elements that prevent the tank from being removed from the housing.

- Disassemble the tank: unscrew the bolts, release the plastic latches, and then remove the top half. If the tank is non-detachable, cut it in half with a grinder.

- Clean all parts thoroughly. rust and scale. Seal with rubber plugs or weld shut any holes that won't be needed later. Leave only those through which the finished juice will drain.

- Weld all the holes in the drum, as they are too large, and drill a large number of small holes around the perimeter.

- Assemble the tank, securing it with screws. For a non-detachable tank, pre-drill holes for the screws.

- Insert the tank back into its original place in the housing, and also return all removed elements: shock absorber springs and sealing rubber.

Next, you need to modify the drum, for this you will need:

- Make a grater by placing pre-prepared strips of mesh in a circle between the ribs of the drum.

- Fix them with small screws.

- Sharpen the blade (striker) that will act as a crushing device.

- Attach the branch pipe to the drain hole.

- Connect the switch and motor to the finished structure, following the electrical diagram.

Making a juicer will not require a lot of additional financial investment, since most of the parts will be taken from the washing machine itself.

A machine assembled this way can produce up to 12 liters of finished product in one hour. Furthermore, the raw materials do not require pre-cleaning or grinding; they simply need to be washed and loaded into the drum.

DIY Apple Juicer

As a rule, winemakers prefer pressing units, since they do not heat the pulp or crush the seeds during operation.

What you will need

Assembling a classic press yourself doesn't require specialized plans or a welding machine. The structure can be made from wood using common tools and fasteners, including:

Assembling a classic press yourself doesn't require specialized plans or a welding machine. The structure can be made from wood using common tools and fasteners, including:

- hacksaw for metal or wood;

- hammer;

- set of screwdrivers;

- bolts, nuts, screws;

- pliers.

Components of the press:

- boards, wooden blocks or slats;

- stainless steel sheet;

- barrel or tank;

- valve;

- piston-pressure;

- metal channel.

It is advisable that the wooden elements be made of oak, beech or birch, since due to their biological activity, coniferous trees change the taste of the sap.

Drainage grates should not be made of chipboard, as dust containing phenol formaldehyde adhesive will enter the finished product.

Step-by-step manufacturing instructions

The algorithm for assembling the pressing unit is as follows:

The algorithm for assembling the pressing unit is as follows:

- To create a stable structure, you can use not only metal but also wood. However, the top crossbar should be made of a metal strip.

- Weld a nut to the crossbar located on the top bar. A screw will be threaded through it to provide a directional load.

- Attach a platform to the base of the screw, which exerts pressure on the raw material in the hopper.

- Make a perforated tank equipped with holes for juice drainage.

- Attach filter fabric to the walls of the tank.

- Install a tank at the bottom of the structure that will receive the finished product.

Important! It is recommended to use lavsan or polyester with a mesh structure as juice filter material.

A properly made juicer will serve you for many years and will help you process a large volume of harvest.